Many businesses need extra space for day-to-day storage, handling and picking activities and yet free headspace often remains unused. Storage equipment providers will tell you that pallet racking will effectively use the overhead room creating better storage density, but as we know, not all businesses need to store more pallets.

There is another way.

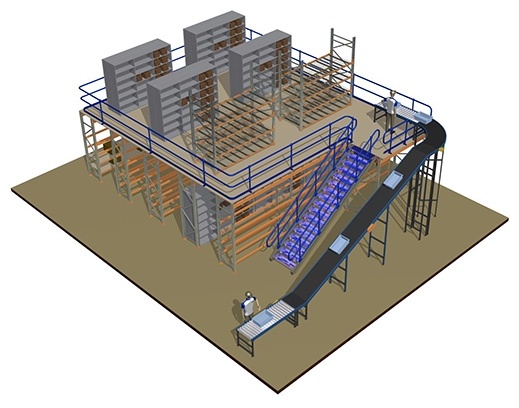

Colby raised storage areas are cost effective solutions that can double the usable floor area of your factory or distribution centre, subject to regulatory approval. They are strong and secure and provide access to new overhead work areas with minimal interruption to ground level workflow.

Low cost, medium-duty floors can be easily assembled using standard Colby pallet racking components to build raised storage areas that are purpose-designed for bulk storage or additional order picking.

And while the extra space can be a valuable asset, the effort required to get stock in and up the stairs is often thought to be too much trouble to be worth it.

There is a solution.

Colby’s extensive range of powered and gravity conveyors can turn your raised storage area into a more efficient and safer workspace. Conveyors add value to overhead workspace by transporting goods from the raised storage area to the ground level for order processing or to replenish stock on the upper level. This is accomplished by using a reversible conveyor that allows product to be moved up and down.

In addition to creating extra space, your employees work safer too. Operator exposure to heavy lifting and the associated risks of carrying bulky goods up and down stairways is almost completely eliminated.

Colby conveyors can easily be integrated into existing raised storage areas. Contact the team at Storage Ideas on 02 9731 7999 who can quickly and easily conduct a free survey of your site and make sensible recommendations of how best to utilise your available footprint.